Precautions for Fan Installation

2024-08-13 10:00:00Proper installation of the fan not only ensures the efficient operation of the fan, but also extends its service life. The following are the precautions for the installation of D-type fans, I hope to help you complete the installation task smoothly.

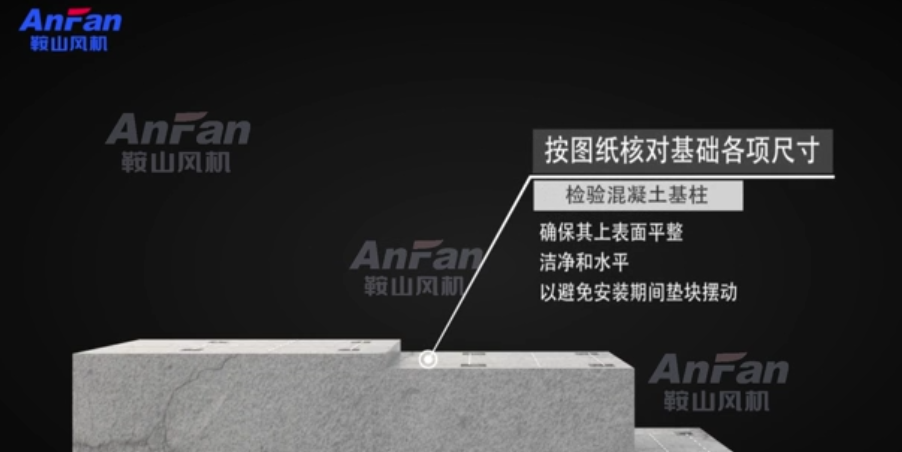

Basic preparation phase

Check the dimensions according to the basic drawings of the fan installation, and find

If the base size is not right, it should be fed back in time.

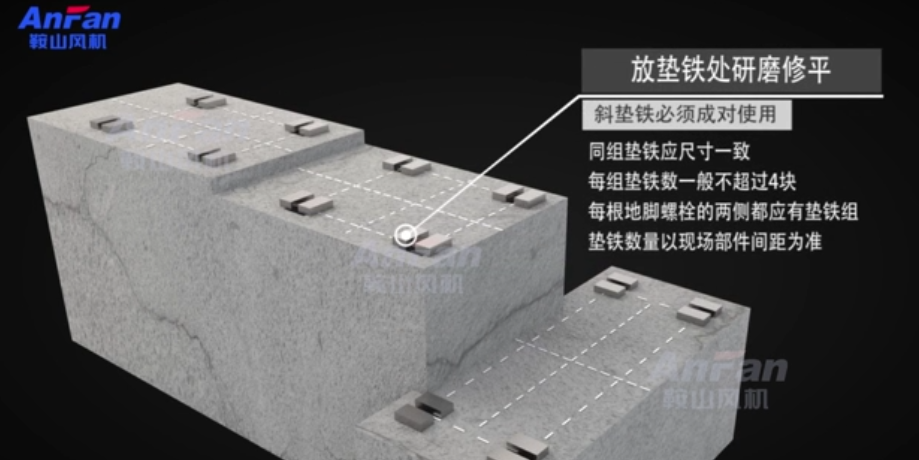

The oblique horn must be used in pairs, the same group of horns should be the same size, the number of horns in each group is generally not more than 4, the total height of the flat horn and the oblique horn shall not be higher than 110mm, and there should be a horn group on both sides of each anchor bolt to avoid the subsequent fan vibration caused by insufficient stability.

Measure the center height of each part, mark the center line of the foundation installation, and the fan installation must be concentric and coaxial, and the standard is within 5 lanes.If it is not marked, vibrations will occur during the operation of the fan.

Precautions during installation

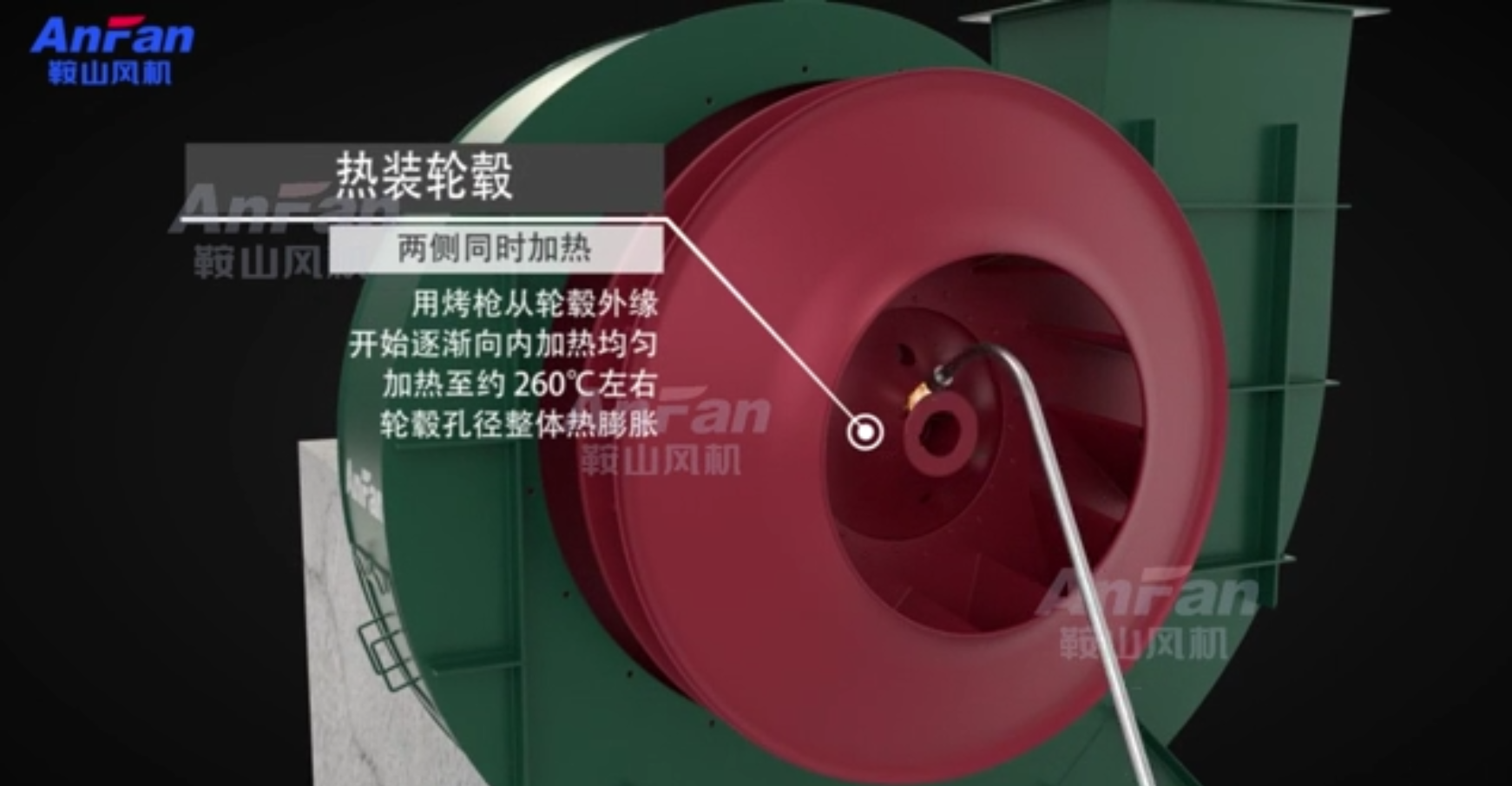

Hot-loaded impeller: The impeller is usually heated to about 260 °C, and the front and rear sides are heated at the same time when heating, and the expansion of the hole can be assembled within 25-30 channels measured by the dial gauge after heating, and the fan may vibrate if the cold-installed impeller is later stage.

Adjustment door installation: the installation part of the adjustment door is rotated left and right, there are different air intake directions, and the main body hair dryer has spraying left and right rotation directions, opening and closing directions and air intake directions, and the installation should be carried out according to the spraying content.

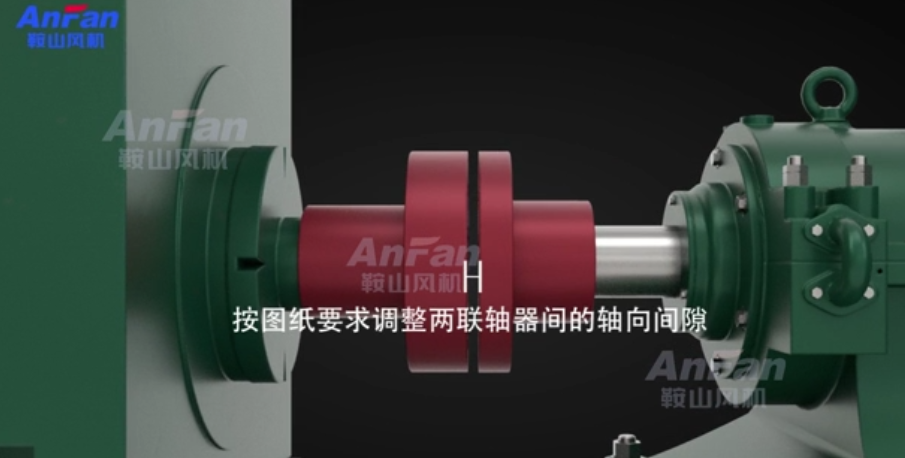

Column pin coupling installation: the main coupling on the main shaft of the fan, and the electric connection at the motor end should be left before the gap, according to the assembly drawing, if the gap is not reserved, the later operation of the fan may have metal friction sound and vibration problems.

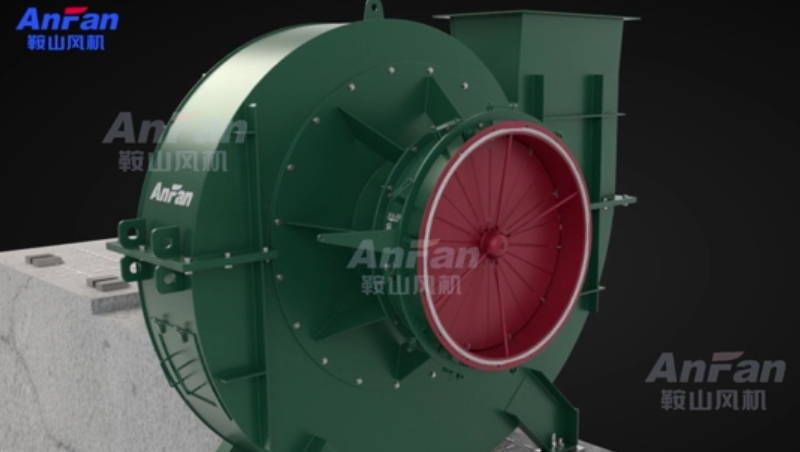

The correct installation of the wind turbine is the basis for ensuring its efficient and stable operation. Through meticulous preparation and standardized operation, you can guarantee the best performance of your wind turbine and extend its service life. If you encounter problems during the installation process, please consult professionals in time to ensure the safe operation of the equipment.