Single Stage Turbine Vacuum Pump

-

High Efficiency

High Efficiency

-

Low Noise level

Low Noise level

-

High Reliability

High Reliability

-

Experienced

Experienced

Flow rate: 50-2500m3/min

Pressure ratio : Up to 3

Efficiency: up to 88%

Service area: Metallurgical. Environmental protection. Chemical. Papermaking.

Product Description

Product Description

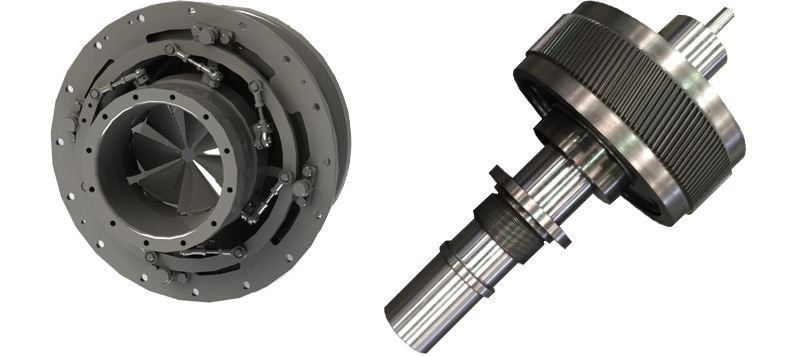

Rotor:

It adopts 3-yuan semi-open impeller and is made by integral milling of CNC five-axis machining center to ensure the accuracy and strength of the impeller.

Inlet guide vane regulator: the airfoil inlet guide vane is used to adjust the inlet air flow pre-rotation Angle of the blower to achieve the performance adjustment of the blower, and the flow adjustment range is 40-110%.

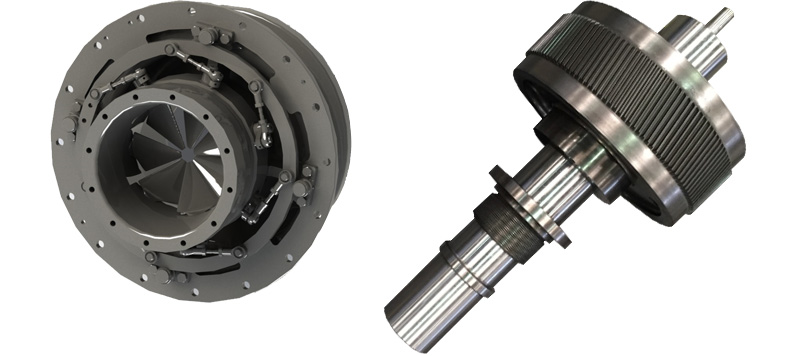

Gear:

The gear is single-sided helical tooth, the precision of the gear reaches the national standard level 5 (5-GB/T 10096), the surface of the gear is specially hardened, and the service life is more than 100,000 hours.

Gear box:

Tilting tile bearing is adopted for high speed shaft of gear box, with high stability; Gear machining up to ISO level 4, design service life is more than 30 years.

· Oil system design: Advanced finite element analysis software was used to analyze the overall stiffness of the oil station to ensure the reliability of support. The oil system is equipped with an oil mist fan. The oil system runs under negative pressure to effectively solve the problem of oil smoke and lubricating oil spatter in the gear box.

The unit adopts direct oil pump for self-forced lubrication, which can be fully supplied by direct oil pump before the blower stops. There is no need to set the high oil tank for on-site power failure emergency oil supply and its supporting oil pipelines. All the oil pipelines are assembled in the plant, and the on-site installation workload is greatly reduced. The auxiliary oil pump only runs temporarily when the unit is started and stops when the unit is in normal operation.

Unit monitoring parameters:

1. Vibration and axial displacement of high and low speed rotor

2. Bearing bush temperature

3. Inlet and outlet pressure, flow rate and temperature of blower.

4. Oil system pressure, temperature, liquid level height, filter pressure difference

Unit control system functions:

1. Automatic control of oil system, including auxiliary oil pump start and stop, oil pressure control alarm stop, oil temperature control.

2. Automatic control of inlet guide vane opening.

3. Vibration and temperature alarm stop of the unit.

4. Anti-surge system of unit.

5. Wheel opening and coordinated control of multiple units

6. Remote online monitoring of unit status and fault diagnosis.

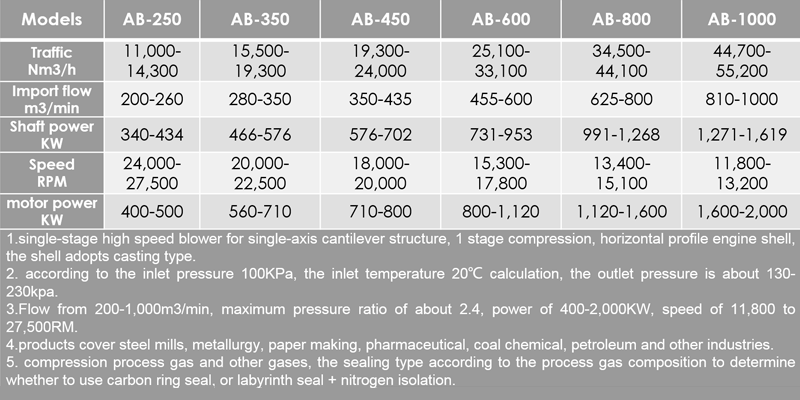

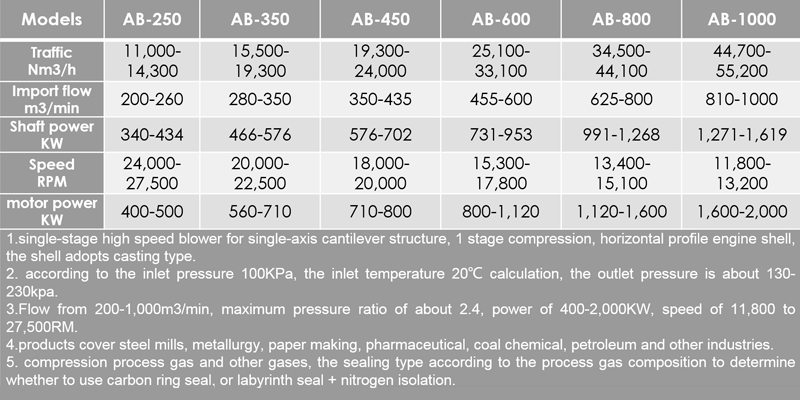

Typical product specifications and parameters:

Service

Service

Why choose service from AnFan?

As a first-class enterprise in the fan industry, Anshan Gangfeng fan has been focusing on the field of high efficiency and energy saving fans for nearly 40 years, and serves more than 3000 customers at the same time.To provide customers with professional and efficient service solutions.

As a first-class enterprise in the fan industry, Anshan Gangfeng fan has been focusing on the field of high efficiency and energy saving fans for nearly 40 years, and serves more than 3000 customers at the same time.To provide customers with professional and efficient service solutions.

1.INSTALLATION&COMMISSIONING

To ensure that a new fan is brought into productive use as quickly as possible, with full confidence that it is correctly installed and commissioned and that all the necessary safety and operational checks have been carried out properly, it is of the utmost importance to have the job either carried out or supervised by people with a comprehensive knowledge of the equipment. The same is true of installing even the smallest spare part.

2.REMOTE MONITORING AND DIAGNOSE SERVICE

AnFan has a remote monitoring and diagnose centre with large data base system, special software and web portal. This center can collect real-time data, analyses and stored data. According to this professional diagnostic analysis graph, system can alert potential problems for customers.

In case equipment break down, professionals will give solutions in first time according to data collected. This service is designed to keep your equipment trouble free, extend equipment life cycle and reduce repair costs effectively.

3.UPGRADE AND RETROFIT

From your maintenance record, we can recommend critical interventions or suggest upgrades that will improve performance or economy. Whether they are for AnFan installations or third party equipment, they are meticulously checked to make sure they are appropriate. And, where possible, through careful upgrades and retrofits, we will advise you on new technologies or developments that might raise the performance, longevity or economy of your equipment.

4.SPARES AND CONSUMABLES

At AnFan, we regard the supply of spare parts and consumables as an essential part of our business, and we treat it with every bit as much care and attention as we bring to new installations. All enquiries and orders are handled by specialist staffs who understand our products and the applications where they are used.

We keep all product and service records, all spare parts orders will be reviewed with the original drawings, to ensure that all products are accurate.

We can set up exclusive inventory for our customers to ensure the timely supply of spare parts. Even for outsourced products, our customers also have strict testing standards for products as a guarantee.

When emergency occurs, saddle wind will be responsible for transporting the product to the scene and responsible for installation.

5.ON-SITE TROUBLE SHOOTING

For more than 40 years, AnFan has the most experienced engineers and troubleshooting experience. From drive and control systems and instrumentation, through to replacing an impeller, we can carry out the entire operation or any part of it you require with the greatest efficiency and in the least time.

We also keep a full and detailed service record for each product. This not only ensures that long term maintenance requirements are met, it provides an invaluable resource when upgrades or enhancements are planned. We safeguard reliability by fully investigating any failures that occur, and preventing their recurrence. Our engineering experience and the feedback we receive allows us to continually improve our maintenance strategies and plans.

6.EPC PROJECT

According to customers' requirements, AnFan can undertake general contract project, including design, procurement and installation, specialized in dust remover, fans, fan ducts, silencer, measuring instruments and PLC control system.